About:

InterBiz, an engineering concern offers consultancy, research, expert advisory, study, feasibility study, product innovation through Research and Development, and training, considering green technology and services like buying house in the field of light engineering sector.

Vision:

To become the one of the leading companies to promote light engineering industries.

Mission:

To achieve target by providing support to our clients.

Main services:

- As consultant, technical advisor.

- Conduct feasibility study.

- Product innovation through Research and Development.

- Training.

- Light engineering buying house.

- Light engineering related publication and audio visual show.

Founder

Chairman

Dr. Syed Md. Ihsanul Karim

Professional Light Engineering Sector Development Specialist with 36 years of experience in the field of import substitute spare parts manufacture, technical training including human resource development and advisory service facilitating, and connecting private sector micro, small and medium manufacturer to achieve quality and productivity.

Dr. Karim is the dreamer and Project Director of Tool & Technology Institute (TTI), for high tech manufacturing...

Dr. Karim is the dreamer and Project Director of Tool & Technology Institute (TTI), for high tech manufacturing technology development as well as Self Employment and Poverty Alleviation (SEPA) for distressed women employment by hands on technical training project under BITAC, Ministry of Industries. In different tenures of his career he worked as the Director General of BITAC and Managing Director of government owned company Small and Medium Enterprises Foundation (SMEF). He has initiated and taken challenge to solve and develop indigenous technology in different fields like radiation leakage of Bangladesh Atomic Energy, high density pump and carbamet solution pump cylindrical block of Bangladesh Chemical Industries Corporation, Hydraulic lift, Centrifuge Machine for salt industries, Coffee Vending Machine, Wind Mill etc. in collaboration with BUET and Bangladeshi expert in home and abroad.

He has taken initiative role for JICA project to develop Light Engineering and Plastic sector of Bangladesh. He is assisting Bangladesh Engineering Industry Owners Association (BEIOA) to implement development project of Long Term Low Interest foreign funding, and Product Development and Training.

Dr. Karim completed BSc and phD in Mechanical Engineering, and M.E in Industrial and Production Engineering (IPE) from Bangladesh University of Engineering and Technology (BUET), Dhaka, Bangladesh.

History

Products made in Bangladesh using local technology through R & D in cooperation with local experts, utilizing Dholaikhal facilities, with BITAC, BUET, and BCSIR serving as testing hubs and technical advisors. These import-substitute technologies are being transferred to the private sector. Most are already operational in their respective industrial areas of Bangladesh, saving a significant amount of foreign currency.

- Vacuum Forming machine for disposable box, plate, and cup factory (2000)

- Hydraulic Cutting machine for disposable box, plate and cup, factory (2001)

- Plastic Sheet Line machine for disposable box, plate and cup, factory (2003)

- Chemical Vapor Deposition machine for BUET research purpose (2002)

- Cylinder Block for Carbamet Solution Pump for Fertilizer factory at the cost of 0.2 crore against the cost of 6 crore from Japan (2012)

- Automatic salt Production Line to modernize existing manual conventional salt factory (2011)

- Coffee Vending machine (2024)

Substituting Foreign Expert

Other works that include substituting foreign experts, high tech, high accuracy critical machineries maintenance, installation, and commissioning experiences:

- In 1990, a heavy-duty, high-accuracy, high-cost Japanese horizontal boring machine weighing 16 tons was relocated from Narayanganj BIWTC workshop to Tejgaon BITAC premises without incurring damage or losing any accuracy of 0.005 mm. This machine was transferred through a ditch, the Buriganga River, and by road. As of 2024, it remains the main machine at BITAC for manufacturing heavy-duty parts with precision.

- In 1994, BITAC designed and manufactured all machinery for a national project of the Ministry of Industries to produce paper pulp from raw jute for all paper mills in Bangladesh through R & D. Dr. Karim was a team member and project head for the installation and commissioning of the project.

- In 2010, Dr. Karim initiated and led an expert team to solve, on an emergency basis, a dangerous radiation leakage at the only nuclear plant in Savar, Bangladesh Atomic Energy, through R & D, risking his life for national interest. This incident was discussed in the national assembly.

- Dr. Karim initiated and led an expert team for the successful first-time local repair and maintenance of the GK project pump, avoiding the need for experts, at a cost of only 3.71 crore as opposed to expending 12 crore for foreign experts.

Products

Manual Waste Compacting Machine

Origin and Manufacturing Country: Bangladesh

Brand: InterBiz

Model: iBm5-25

Specifications:

- Bail size: 16"L x 16"W x 16"H.

- One person operation.

- Easily moveable by wheel.

- MS reignforced body.

- Two-axis four-lines stitched bail body.

- Production capacity: Approximatly 40-60 kgs of plastic

Hydraulic Waste Compacting Machine

Origin and Manufacturing Country: Bangladesh

Brand: InterBiz

Model: iBh2-25

Specifications:

- Bail size: 24"L x 18"W x 24"H.

- Machine size: 32"L x 20"W x 120"H.

- Cylinder diameter: 3.5".

- Piston diameter 2".

- Piston stroke 30".

- Operating pressure 150 Bar (Total approximate load: 10 tonnes)

- Bail weight for plastic waste 15-20 kgs.

- Machine weight: 300 lb.

- 1.5 KW single phase motor, 220 AC power supply.

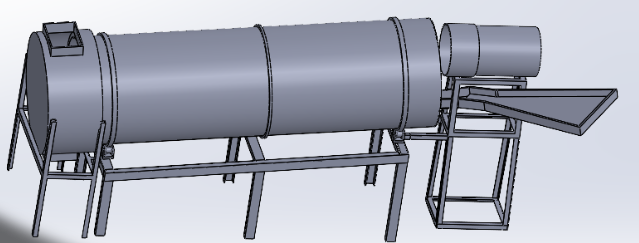

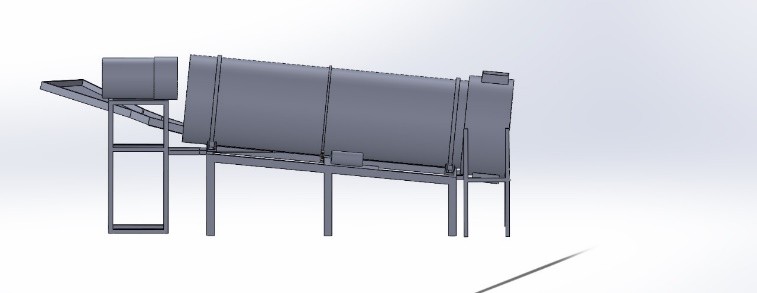

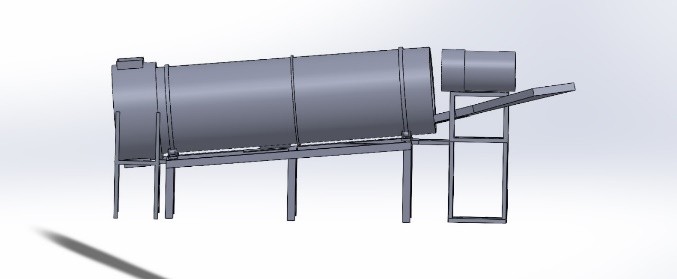

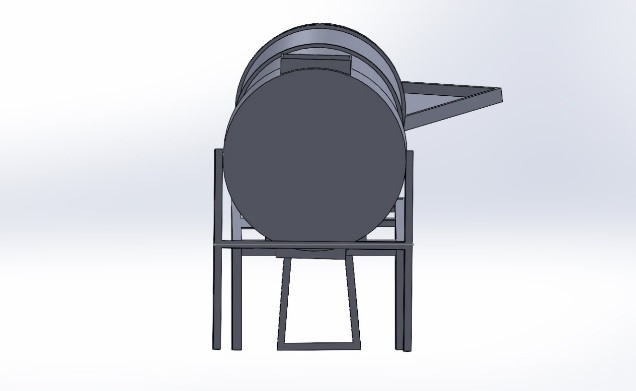

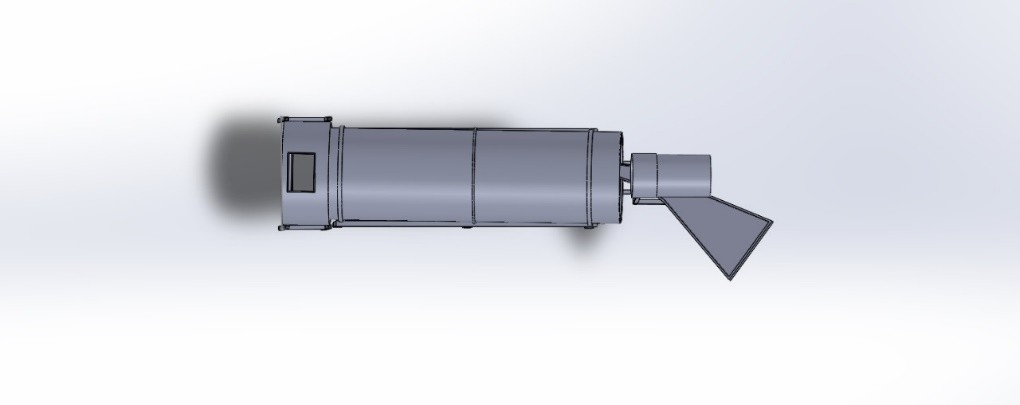

Solar Rotary Compost Dryer

Origin and Manufacturing Country: Bangladesh

Brand: InterBiz

Model: iBdry2-25

Specifications:

- Machine size: L-5500 mm, B-1220 mm, H-2440 mm.

- Solar cell 2300 Watt.

- 2.2 KW Solar controller.

- Production Capacity: Compost-200 kg/hr.

- Drum Diameter: 1150 mm.

- Drum Length: 3200 mm.

- Power: Three phase, Heater - 21 KW, Rotary Drive motor - 1.5 KW, Solar Blower Motor - 1.5 KW.

- Drum Rotation Inverter Control.

- Working surface Epoxy paint coated.

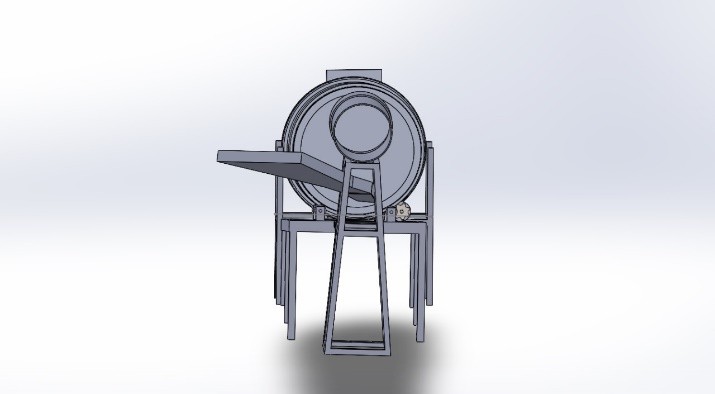

Coconut Shredder & Defibering Machine

Origin and Manufacturing Country: Bangladesh

Brand: InterBiz

Model: Coco-500

Specifications:

- Machine size: 1500 mm x 1450 mm x 1500 mm.

- Capacity: 500 kg/hr.

- Power supply: 415V/3ph/50Hz.

- Power rating: 15 hp.

- Machine weight: 850 kg.